The UV-200 inline curing tunnel is designed for efficient curing of UV or visible light sensitive adhesives, inks and coating materials.

A variety of lamps are available to meet the requirements of a wide range of applications. The system is designed with complete UV shielding as a safety measure and for optimized cure results. Flexible configuration options allow for the lowest cost of ownership while meeting your needs.

Download

Download

- Complete UV shielding

- Adjustable exposure time

- Adjustable conveyor width up to 600mm

- Adjustable conveyor speed control

- Adjustable lamp height

- Lamp life monitor

Curing system |

UV200-M |

UV200-L |

|

Lamp type and brand |

Mercury lamp |

Metal halid lamp |

|

UV lamp type |

Electric arc |

Electric arc |

|

Lamp active wattage |

8KW |

8KW |

|

Number of lamps |

2pcs |

2pcs |

|

Lamp lifetime |

3,000h |

3,000h |

|

Reflector lifetime |

8,000h |

8,000h |

|

Effective irradiation width of a single lamp |

300x600mm |

300x600mm |

|

Effective irradiation area of the oven (LxW) |

600x600mm |

600x600mm |

|

Lamp length |

770mm |

770mm |

|

Lamp diameter |

25mm |

25mm |

|

UV spectrum wavelength |

200-440nm |

200-500nm |

|

Main band |

365nm |

365+395nm |

|

Light intensity |

2,500mw/cm² |

2,500mw/cm² |

|

Adjustable power levels |

YES |

YES |

|

Lamp configuration in machine |

Upper conveyor lampx2 |

Upper conveyor lampx2 |

|

Light traps on the top module |

YES |

YES |

|

Light traps on the bottom module |

NO |

NO |

|

Lamp height adjustment |

Manual adjustable 40-110mm |

Manual adjustable 40-110mm |

|

Cooling method |

Air cooling |

Air cooling |

|

Exhaust fan with low level flow alarm |

YES |

YES |

|

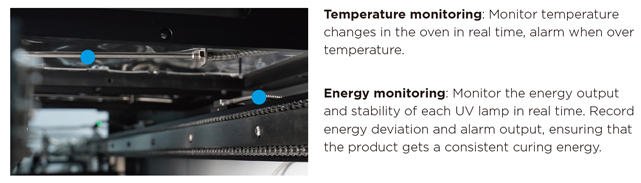

UV temperature measurement sensor |

YES |

YES |